Etched Honeycomb Processing is a leading surface technology used in high-end stainless steel cookware. It combines chemical etching with a non-stick coating to create a textured surface that significantly improves cooking performance.

Technical Principle

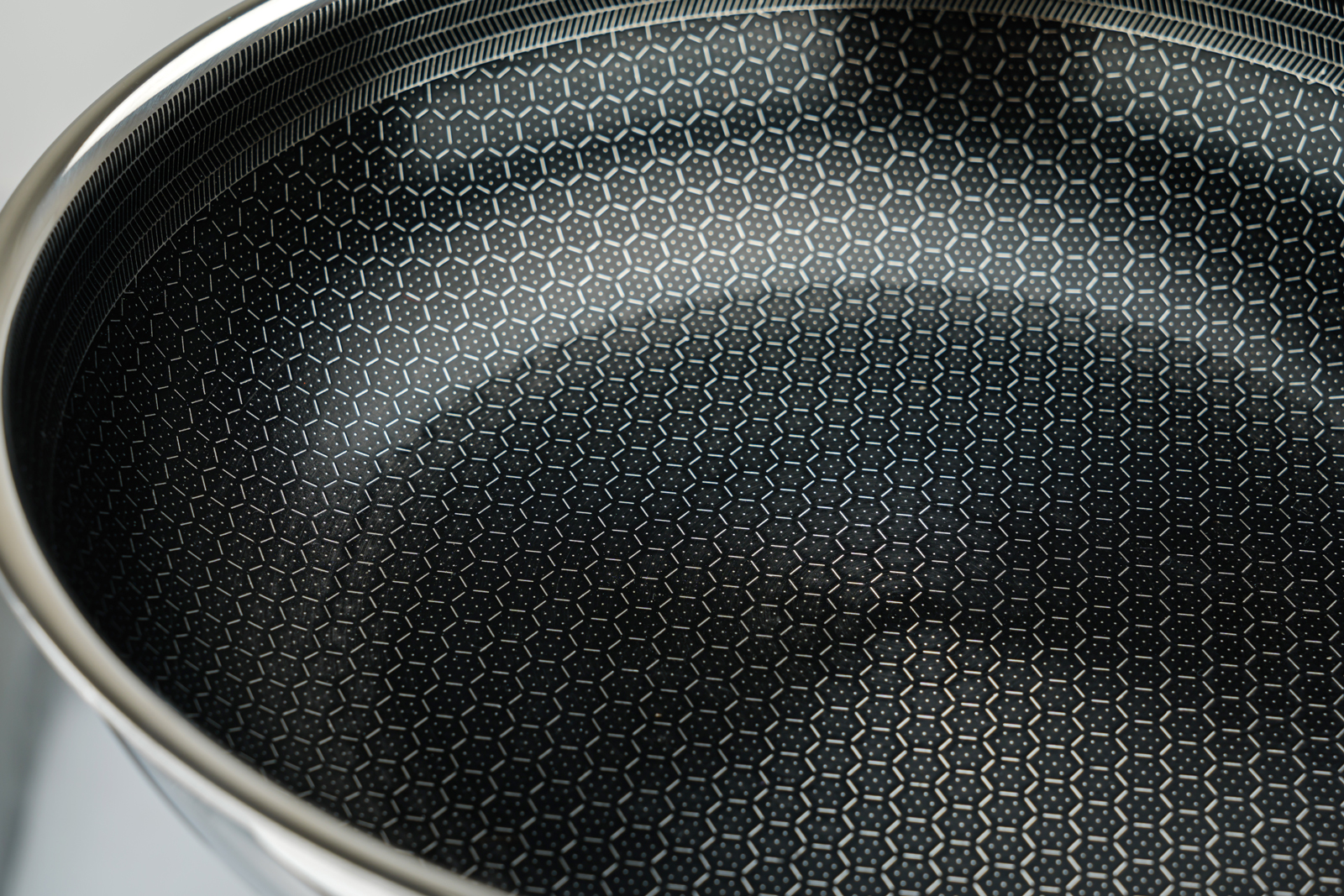

This process involves using laser or chemical etching on the interior wall of the pan to create a dense network of hexagonal honeycomb ridges. These raised ridges are made of stainless steel, while the recessed “valleys” between them are filled with a non-stick coating.

Key Advantages

Scratch Resistance: The raised stainless steel grid acts as a physical shield. Since the spatula primarily contacts the hard steel ridges rather than the recessed coating, you can safely use metal utensils without damaging the non-stick properties.

Superior Non-Stick Performance: The design creates a “suspension” effect. Food sits on top of the honeycomb structure, supported by the coating and a layer of steam, resulting in excellent food release while being more heat-tolerant than traditional pans.

Even Heating & Energy Efficiency: Often applied to multi-ply bonded metal, this structure ensures rapid and uniform heat distribution. This reduces localized hotspots and minimizes oil smoke, making it ideal for high-heat searing and stir-frying.

Easy Maintenance: Compared to traditional stainless steel pans, the etched surface prevents stubborn charring, making it much easier to clean with just a simple rinse or wipe.